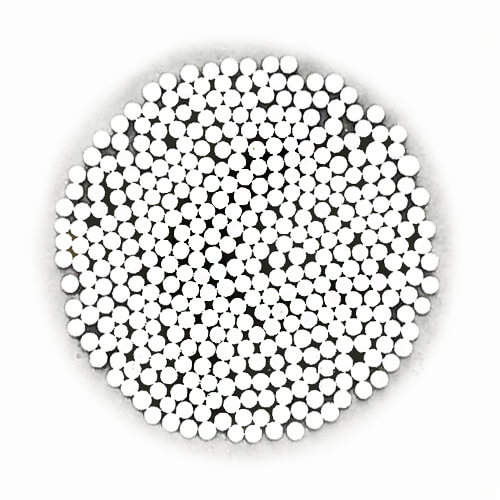

C Stone – Ceramic

Description:

C Stone – Ceramic after refining natural stone which contains AI2O3, SiO2, Fe2O3, CaO, Na2O3, etc., and compounding the material to be perfect crystal under certain chemical calculations.

C Stone is made and hardened by heat at 1,300˚C – 1,400˚C. The specific gravity is 2.3 – 2.6 and C Stone shows excellent efficiency in finishing and polishing job.

SELECTION OF BARREL STONE

| SHAPE | USAGE |

|---|---|

| Type T (Triangle) | Most suitable for rough grinding of all metal and non-metal and economical media owing to large removal |

| Type R (Round Pole) | Medium grinding and finishing for burrs and surface. Especially suitable for recessed shapes. |

| Type D (Diaper) | Suitable to cut grinding time by the highest efficiency for large and thick materials. |

| Type B (Sphere) | The mast is suitable for getting a beautiful and smooth surface due to the choice of the compound and internal finishing. |

| Type C (Special Type) | Finishing media and the most suitable for complicated shapes and precision parts. |

Categories: Ceramic Grinding Media, > C Stone - Ceramic

Tags: C Stone - Ceramic, Ceramic Grinding Media