HIGH PRODUCTIVITY

we pride ourselves on offering the best alternative methods that result in higher productivity rates at competitive prices across various industrial operations.

CUSTOMER SERVICE

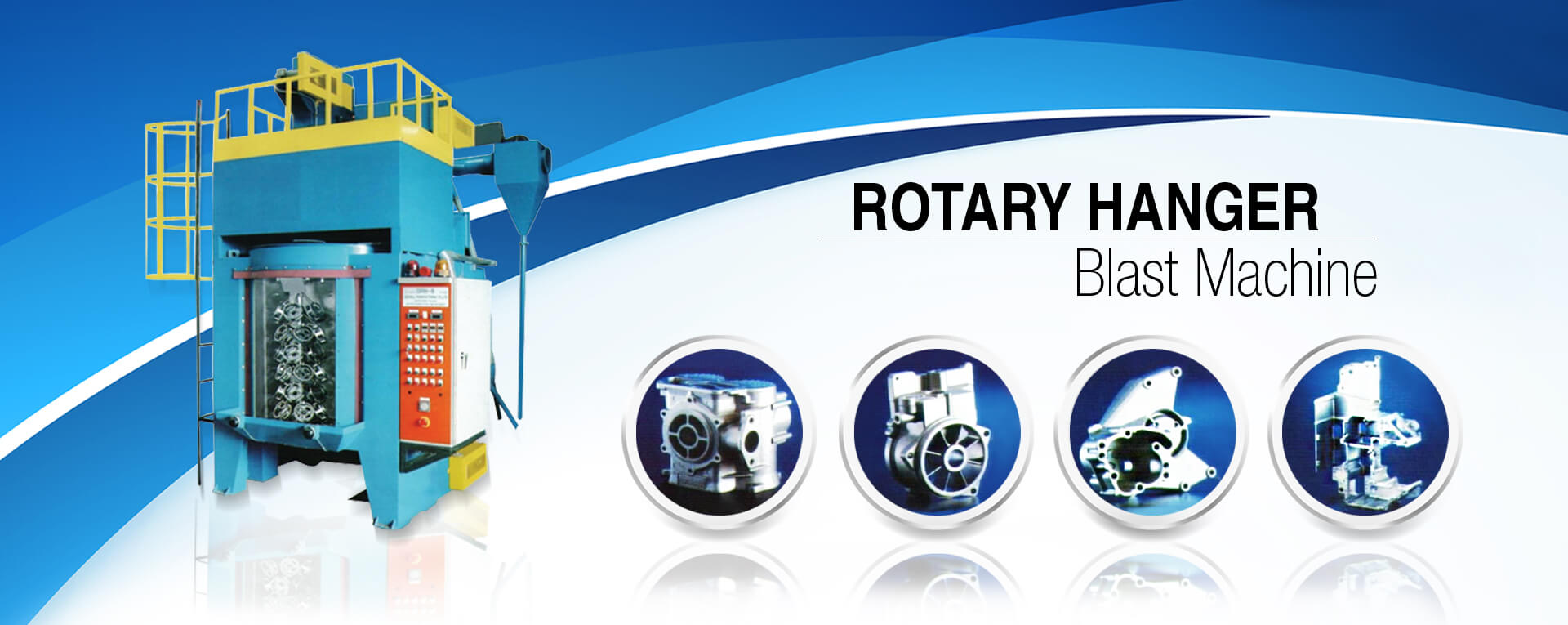

We provide after sales services for all types of shot blasting machines and equipments. Due to practical methods of operation and provision of alternatives for various work-pieces, we maintain high productivity while providing low cost services in various industries.

QUALITY ASSURANCE

We are committed to delivering superior products and services to meet the evolving needs of our clients. By combining our technical expertise, excellent customer service, and top-quality products, we have earned a strong reputation in the industry.

BLASTING WORK SOLUTION

GMSB Engineering Sdn. Bhd.

is a reputable distributing and service organization that was established in 2008. Located in Nilai, Negeri Sembilan, we specialize in providing after-sales services for Shot Blasting / Peening of items and Dust Control systems.

With a strong focus on surface preparation, we pride ourselves on offering the best alternative methods that result in higher productivity rates at competitive prices across various industrial operations.

Our team consists of highly skilled and experienced professionals who are dedicated to providing exceptional after-sales technical services to our valued customers. We also offer high-quality spare parts to ensure the optimal performance and longevity of the equipment we service.

At GMSB ENGINEERING SDN BHD, we understand the importance of using the right abrasive media for different applications. That’s why we offer a wide range of abrasive media options, including steel grit & steel shot, stainless steel shot, aluminium oxide, glass beads, ceramic media, and more. Our selection ensures that our customers can find the most suitable abrasive media to achieve their desired surface finish and cleaning requirements.

FEATURES PRODUCTS

ABRASIVE MEDIA

Aluminium Oxide have the characteristics of high hardness, sharpness, tenacity, stable chemical property, heat resisting and corrosion resisting. This abrasive is fast cutting and does not contain free silica. It gives a matte finish, or produce anchor patterns on most metal surfaces and can be used economically in a closed system blasting machine.

Glass Bead is a unique and popular air blasting abrasive for cleaning and conditioning surfaces. It is manufactured from high-grade glass, annealed in its spherical shape to equalize internal stresses and resist fracture. In addition, the inherent strength of glass bead is such that it can survive multiple impacts, allowing for economies of continuous recycling.

Stainless Steel Shot are widely used for cleaning, de burring surface improvement from conventional steel shot. Stainless steel shot provide rust free condition after blasting and metal colour remain after blasted.

Stainless steel shot commonly apply for non-ferrous metal casting, industry, automotive, motorcycle, ship building metallurgy machinery…etc surface preparation.

Stainless Steel Shot are widely used for cleaning, de burring, surface improvement from conventional steel shot. Stainless steel shot provide rust free condition after blasting and metal colour remain after blasted.

Stainless steel shot commonly apply for non-ferrous metal casting, industry, automotive, motorcycle, ship building metallurgy machinery…etc surface preparation.